Downloads

Here you will find download links for updates and digital products. Our very own Controller Software is available below, it’s updated regularly and you’ll be notified each time a new version is uploaded.

User manuals

Use these download links to access your user manuals. View on-screen or print out at your convenience

Xcalibur

Tolerance Puller

Pro/Pro HT

Winder 2

Touch

fusionX

Pelletiser

Dehydrator

Full System

Nexus

Water Bath

Xcalibur

Tolerance Puller

Pro/Pro HT

Winder 2

Touch

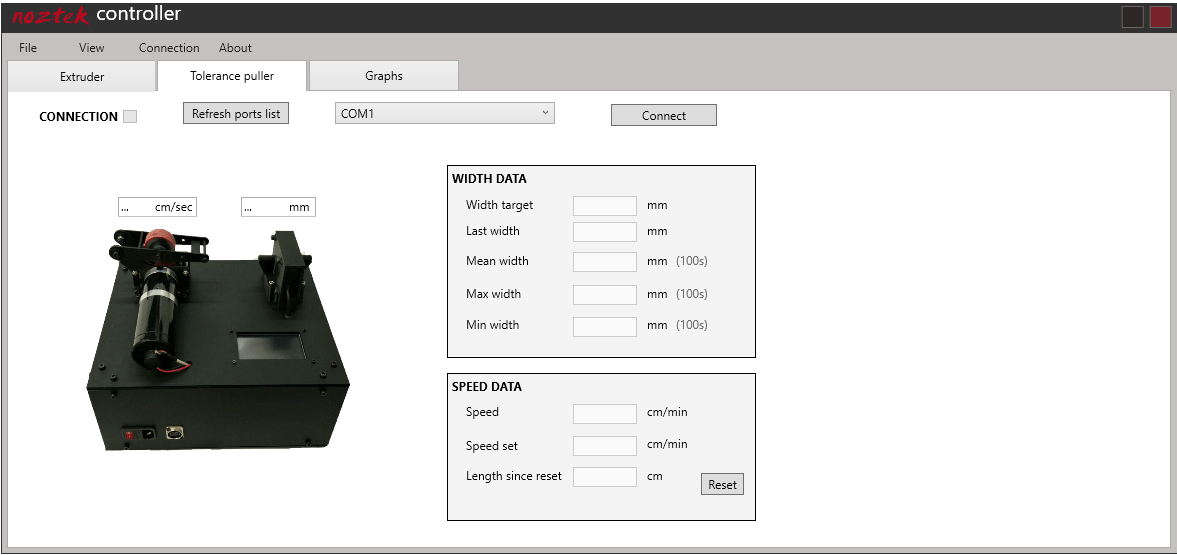

Noztek Control Software Management

Make sure you add CH340/CH341 USB to serial port Windows driver, supports Windows XP/Vista/7/8/8.1/10/11/

https://www.wch-ic.com/

Click the link button below and you download will begin

Research & Development Capabilities

Process Optimization Tools

Advanced features support systematic process improvement:

- Parameter correlation analysis identifies optimal processing conditions

- Statistical process control with capability studies and trend analysis

- Experimental design support with automated data collection protocols

- Comparative batch analysis for material and process development

- Process validation documentation for regulatory compliance

Quality Assurance Integration

- SPC (Statistical Process Control) charts with control limit calculations

- Capability index calculations (Cp, Cpk) for process assessment

- Automated quality reports with pass/fail criteria evaluation

- Traceability documentation for material batch tracking

- Audit trail maintenance for regulatory compliance requirements

Professional Application Benefits

Research Institution Advantages

- Publication-quality data with comprehensive process documentation

- Experimental reproducibility through precise parameter control

- Grant compliance with detailed process validation capabilities

- Student training with intuitive interface and comprehensive data collection

Industrial Development Benefits

- Process scalability assessment through detailed performance analytics

- Quality system integration with existing manufacturing protocols

- Cost optimization through material usage and efficiency analysis

- Regulatory compliance with comprehensive documentation capabilities

Advanced Analytics & Reporting

Built-in Analysis Tools

- Process capability studies with automated report generation

- Correlation matrices for multi-variable process optimization

- Control chart generation with customizable control limits

- Performance benchmarking against historical data sets

Custom Reporting Features

- Automated report generation with customizable templates

- Executive summary dashboards for management oversight

- Technical data reports for engineering analysis

- Quality compliance documentation for audit requirements

- Process optimization recommendations based on data analysis

System Requirements & Integration

Hardware Compatibility

- Windows 10/11 compatibility with standard laptop/desktop systems

- USB connectivity for direct equipment communication

- Minimum system requirements optimized for smooth operation

- Multi-monitor support for enhanced process visualization

- Network connectivity for data sharing and remote monitoring

Software Features

- Intuitive user interface designed for both novice and expert users

- Comprehensive help system with contextual guidance

- Automatic software updates for continuous feature enhancement

- Data backup and recovery systems for process continuity

- User permission levels for secure multi-user environments

The Noztek Professional Control Software transforms desktop extrusion equipment into a comprehensive, data-driven manufacturing platform that meets the demanding requirements of research institutions, product development laboratories, and quality-focused production environments.

Virtual Products

Clear Filament Adapter for Noztek Winder 2

With this new filament adapter, you are able to use our winder 2 to spool transparent (colourless) filament.

Simply 3D print this downloadable product and fit onto the sensor element of your Winder.

Compatible with Noztek Winder 2.0

Click the download link button below and your download will begin